Sep 29, 2023

American Manufacturing Is Coming Back, at Least in Los Angeles

, Bloomberg News

(Bloomberg) -- The US has an important moment ahead of it. After spending decades sending manufacturing jobs overseas, America rather miraculously finds itself at the forefront of a new era in production.

Thanks to advances in artificial intelligence software, computer vision and materials, startups across the country are creating very sophisticated, automated manufacturing machines and factories. This is robots but better, smarter robots. It’s building-sized 3D printers. It’s mom-and-pop tooling operations being replaced by thousands of thinking machines, and the latest episode of Hello World takes you inside the factories.

On This Episode

Nowhere is this trend more obvious than in Los Angeles. The city’s long-held automotive and aerospace traditions have been upgraded by a wave of startups. In many cases, veterans of Elon Musk’s Space Exploration Technologies Corp. have taken the skills they learned at the rocket maker and applied them to new fields. This great SpaceX diaspora has placed Los Angeles at the center of the US’s attempt to revitalize and modernize its manufacturing infrastructure.

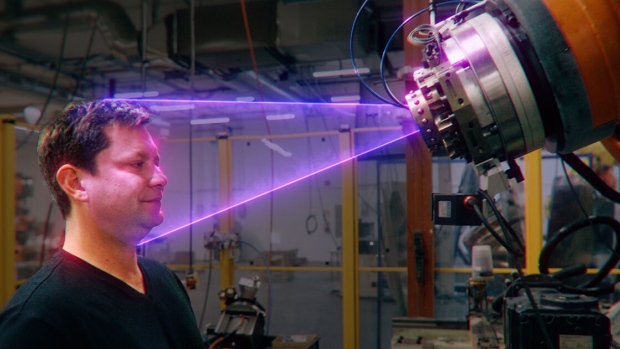

For this episode, I headed to Los Angeles to trace its manufacturing roots and to explore what this new industrial future might look like. It’s a get-your-hands-dirty-and-then-have-two-robots-build-your-face-out-of-metal type of adventure.

Things You Will Learn

The heart of LA’s new manufacturing scene is in the cities-cum-suburbs of Hawthorne and El Segundo. These are not the prettiest locales in LA — at all — but they are serious, up-and-coming economic engines.

Anyone driving through either city will see the roots of LA’s industrial base. Boeing, Lockheed Martin, the US Air Force and others all have massive compounds lining the streets. SpaceX, of course, also has its headquarters in Hawthorne with a rocket body resting in the parking lot to mark its territory.

Dig a little deeper, though, and you’ll also find the buildings of companies like Freeform Future, Universal Hydrogen and Hadrian Automation, which are all revamping manufacturing technology in different ways.

If these companies and their peers are successful, the US could leap ahead of other nations in terms of building things for industries like aerospace, automotive, energy and construction. These modern manufacturing methods allow for greater customization of parts, more complex designs and greater automation.

The downside of this revolution, of course, is that it will not produce the same number of jobs. The goal here is to move from factories filled with people to factories filled with robots and giant 3D printers.

Things to Do After Watching the Episode

My time in California began at Pomona College. (It was much easier to get in all those years ago when I enrolled.)

Pomona is based in Claremont, California, and is connected to several other colleges, including the engineering powerhouse Harvey Mudd College. There’s every chance you’ve never heard of Claremont, but it’s an idyllic little city, and the campuses at its core are stunning. If you want a pleasant weekend on a sunny day in LA, you could do worse than spending it in Claremont.

Right next to Claremont is the actual city of Pomona, where famed metal shaper Bobby Walden has his shop. Walden offers courses in metal shaping now and again, and he’s probably the best teacher you’ll find.

©2023 Bloomberg L.P.